End-to-End Control

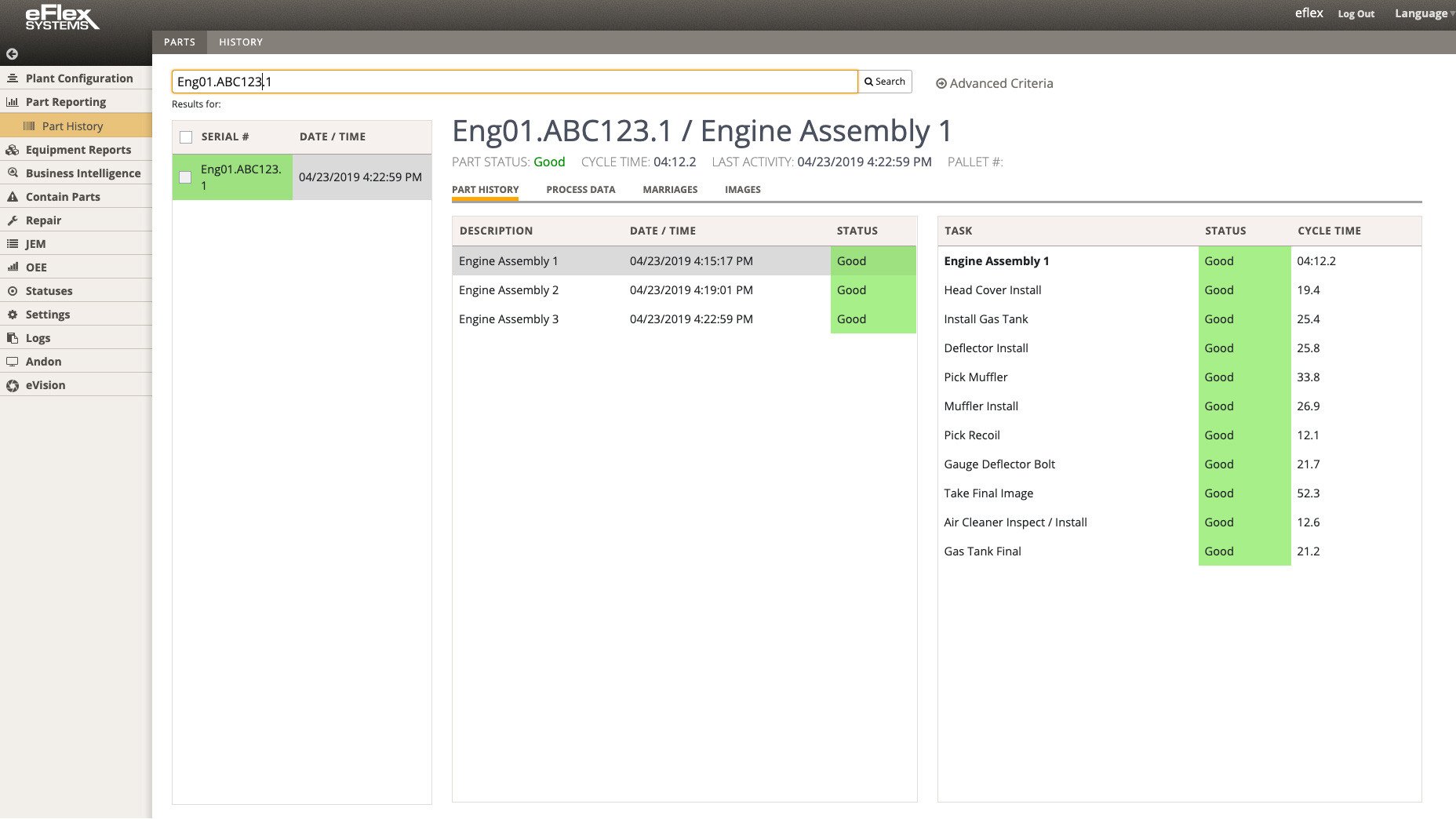

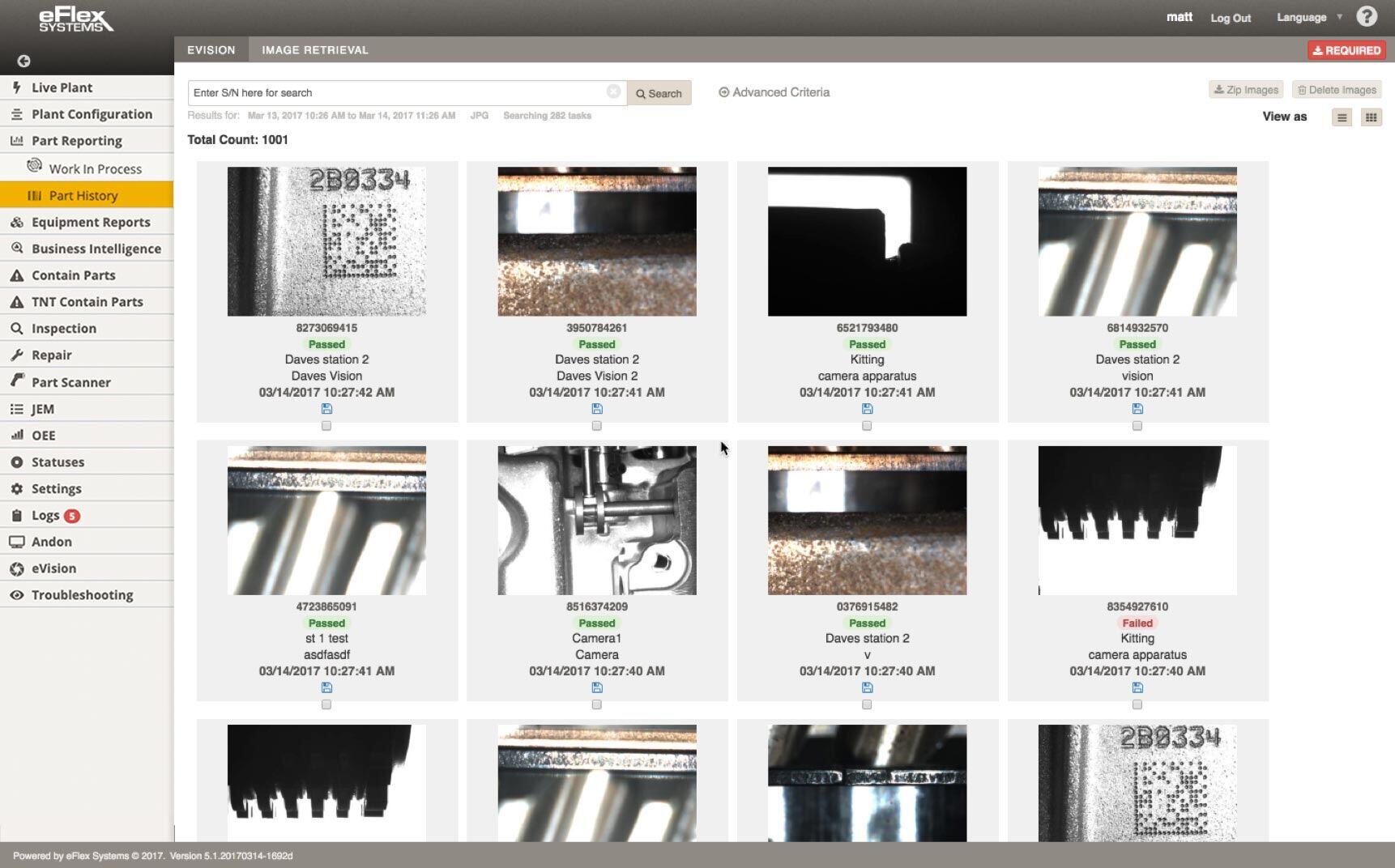

Track & TraceGain full control over your production process with precise tracking of every product and component. Connected Process Control provides real-time genealogy data, giving you complete visibility to prevent errors, improve quality, and ensure compliance at every stage of production.