What’s the Best Method for Storing & Organizing Part Inspection Images from Your Manufacturing Process?

by Dan McKiernan, on Sep 23, 2015 4:43:00 AM

Manufacturers are beginning to realize the need to retain images as product is processed through their systems to help with warranty claim management, improve quality and perform root cause analysis. Vision image inspection systems have been growing in recent years because the need for improving assembly line inspection and quality, in conjunction with reduced personnel, has driven demand towards “automated” inspection. Fortunately for manufacturers, vision inspection system prices are dropping and suppliers are coming out with lower cost models which are capable of sophisticated error proofing and file handling. This short guide will help you sort through the features and options to determine what capabilities you want and need.

Image Storage Location: Local PCs, Network Drive and Web-Based

There are three main ways to store process images.

Option 1 - Local PCs: Some manufacturers simply store images on local PCs scattered across the plant floor. This is costly and difficult to maintain due to the excessive life-cycle cost and labor involved with the initial investment, ongoing OS patches, virus updates and hardware failures. It also forces engineers visit each PC storage area to retrieve images.

Option 2 - Network Drive: Some manufacturers configure plant floor cameras to send images to network drives. This architecture requires manual monitoring of disk space and typically requires the use of a file explorer to search for images in folders. Other issues with this system include:

- Images can be deleted or moved by mistake

- Thumbnail viewing can cause system crashes

- No notification when images are not being sent/stored

- Difficult to determine which drive to access

- No data reporting or analysis capabilities such as reject rates, lighting trends, or top rejecting camera Pareto charts, to name a few.

Option 3 - Web-Based Central Storage System: A central storage system can save thousands of images per minute with associated data, and provide diagnostics when images are not being stored. A comprehensive solution should provide for a web-based retrieval and reporting system which also assists plant personnel in identifying problem vision systems, processes, or parts. For example, warning and alarm conditions can be generated and emailed when inspection systems reach predetermined reject rates. Statistical analysis can determine correlation between rejects and luminosity, distance, or focus. Alarms can be sent when part mark grades begin to deteriorate. P-charts can be generated to quantify application changes.

Vision Image Storage Capabilities & Features

There are numerous capabilities and features that can be utilized through a web-based central storage system, which are not available through options 1 and 2 listed above.

Search Criteria

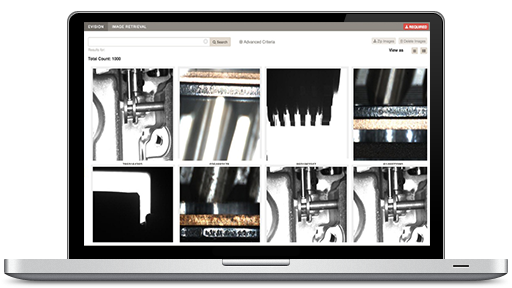

To do any detailed analysis, images must be searchable by specific criteria such as part serial number, station, camera, pass/fail, retry count and or date/time range. Images can be put through the imaging application software to determine if the failed part would still pass with current applications, or applications could be modified in order to catch the failure for current manufactured parts. Depending on the software you are using, images can be viewed in varying formats such as carousel, grid or gallery, or exported to a zip file with a browser image viewer.

Managing Warranty Claims

When a part or product is returned with a warranty claim, the archived images can be used to determine whether or not the plant is at fault. If the plant has evidence to prove it is not at fault, then no charges are made. Vision inspection can be hugely beneficial in not only proving no fault in a warranty claim, but also preventing a warranty claim from occurring. Visions systems help prevent defect parts from getting to the customer by providing detailed dimensional information that can be used to identify the root cause of defects and alerting engineering to degrading applications and supplier products.

Root Cause Analysis

When a product is returned, engineers need to search through images to see if they can determine the root cause of an issue. If the images are stored on local PCs or with a system that doesn’t offer this type of analysis and detail, the manufacturer is left with no clear course of corrective action. If a central storage software system is used, images of other parts which were manufactured at the same stations and time, or with the same lot of supplier parts, can be reviewed to determine if a part was manufactured properly or if a larger product problem exists.

Running Challenge Parts

Traditionally, vision systems are periodically tested by running challenge parts with specific defects through the vision system. Time and money is required to produce and store challenge parts and downtime is often required to run them through the vision system. These expenses can be avoided if images of defective parts are stored on a central server and can be analyzed to test the configuration of the vision system, all while avoiding the expense of creating, storing and running challenge parts.

Monitoring Part Quality In Real-Time

Predictive reporting and alarming can be configured to statistically monitor reject rates, lighting, part marking grade, part positioning and generate warning and alarm events that notify users of degrading conditions at a particular camera. Additionally, the camera connection status, camera image rate, date and time of last file, and other information should be monitored.

Conclusion

Manufacturers who generate a large number of process images and seek better monitoring and preventive reporting for inspection systems should consider utilizing a vision inspection system with a web-based central storage system, such as eFlex Vision. For more information, you can download our Vision brochure.