Advantages of Digital Manufacturing Traceability & Product Genealogy

by George Jewell, on Nov 11, 2019 8:03:46 PM

At its core, manufacturing is about stuff. Taking small things and putting them together in ways that create bigger and more sophisticated things. Refining raw materials into more complex and usable substances. Even the most cutting edge processes and products start with the basics, the ingredients: the stuff.

Which is why keeping track of that stuff is so critical to manufacturers. Better monitoring and tracking for component parts and materials helps reduce waste, boost efficiency, increase quality, and even minimize liability. The ability to extend that tracking capability through finished products is even more of a game-changer. Manufacturing professionals have long experimented with new and different ways to keep track of products and monitor materials. In recent years, some powerful new systems have begun to emerge that, for the first time, have achieved the track and trace holy grail of true part genealogy reporting: traceability and process data storage for every part status, from supplier to customer.

Leading manufacturing traceability and quality control software solutions like the eFlex Track & Trace platform enable users to store, retrieve, and report part status in a manufacturing environment with a previously unthinkable degree of part-specific precision. State-of-the-art software, in conjunction with streamlined plant floor controller logic unlocks real-time part storage, status, marriage, tracking, RFID recovery, quality gates, and reporting.

Genealogy is the line of descent—quite literally the origin story—of a person, place or thing. Achieving that level of “genetic” specificity with parts and products makes it possible, for the first time, to practice true quality process management: enabling, enforcing and tracking the quality process to reduce production costs and meet regulatory standards. Solutions like the eFlex Track & Trace platform deliver that functionality along with plant floor production visibility: connectivity and tracking/monitoring that provides both real-time and historical production visibility for part status, work-in-process, and genealogy.

The advantages of this new generation of manufacturing traceability and quality control software solutions are potentially game-changing:

- Flexible and easy path configurations - Ability to easily configure digital assembly processes and path configurations – ensuring all build prerequisites are checked at each station.

- Robust rework/repair strategies - Easily define in your process configuration whether a part from a station is allowed to be reworked. Capture reason codes and process data for all reworked/repaired parts.

- Easily contain suspect parts - Quickly identity bad parts, contain them and stop production on those parts – ensuring First Time Quality (FTQ) scores remain exceptional.

- Part marriage and divorce capabilities - Any number of parts can be married or divorced at any station as each is performed asynchronously. Ability to confirm that married parts/components passed previous operations and are not contained.

- Process data collection from operator and keyboard wedge - Easily capture manual process data from operators with unlimited data collection options and capabilities.

- Plug-n-play IoT device integration - To further eliminate errors, easily connect, enable and control IoT devices in the assembly process. Capture process data from devices such as fasteners, gauges, scales, barcode scans, pick lights, vision systems, AR, cobots and more.

- Data-driven notifications - If a process data point is out of spec, such as exceeded WIP targets, out of control data or cycle times, receive automatic alerts and notifications.

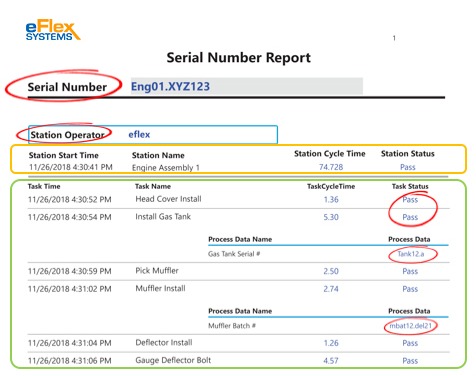

- Detailed reporting and part genealogy- Numerous web-based reporting capabilities for queries and reporting on part status, station, date/time, cycle times, images, process data, containment, rework/repair, diagnostics/events, production history and more. Get a digital birth certificate for every product built down to the component and task level. Proof that your products were built correctly and compliance standards met!

When deployed alongside streamlined plant floor controller logic, manufacturers can achieve extremely fast, sub-second response times, with a system that simultaneously provides real-time responses from hundreds of connected stations. The best new platforms are available as a simple and easy turnkey traceability solution that saves in-house resources and leads to near-immediate ROI.

Paperless tracking, archiving and intuitive reporting helps provide unprecedented clarity and visibility that empowers decision-makers. This newly detailed, permanent digital record allows for precise tracking and robust traceability and product genealogy to enforce correct builds and quality standards.

In other words, for the first time in history, manufacturers can control every element of that all important stuff that goes into making a product. Unprecedented transparency and visibility and newly precise control over the ingredients leads to a controlled, consistent and high-quality finished product. It reduces production costs, ensures brand consistency, protects consumers, minimizes liability exposure, and ensures compliance with regulatory and compliance standards. And it gets manufacturers to a place that was previously considered to be a pipe dream: a place where error-free outcomes and near-perfect quality control are realistic and achievable goals.